Realizing high-strength and lightweight products with metal lamination technology handling complex shapes

-

-

Introducing the Latest Metal Additive Manufacturing Machine

By Introducing SLM Solutions SLM500HL * from 2016, shapes that cannot be obtained by machining or casting are now available.

Modeling area280 mm × 500 mm × Height 325 mm

Topology Optimization Recommendations

It allows next-generation product modeling with excellent functionality and design which has begun to appear in Europe and the United States

- 1

-

New Component Design Platform

High value-added product design unrealized by conventional manufacturing methods

- 2

-

Application of Bionic Design

Products utilizing the characteristics of AM (Additive Manufacturing)

- 3

-

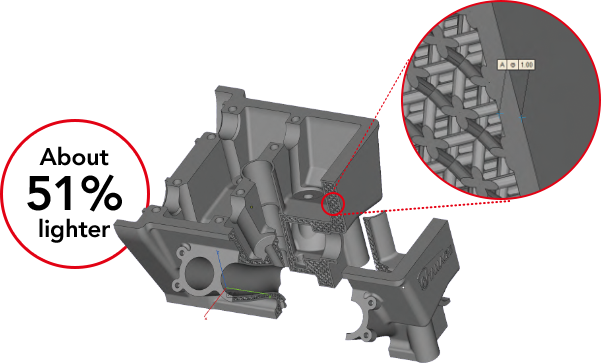

Shape Optimization

Allows high-strength light-weight, space optimization

- 4

-

High degree of freedom

Appearance impact by original design

- 5

-

Optimization of production efficiency

From prototype to mass production

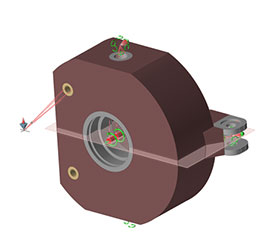

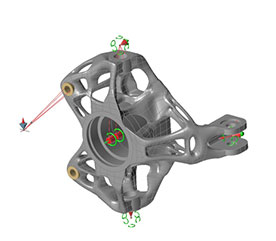

Topology Optimization Items

Effective for high-load, high-intensity items such as suspension arms, suspension uprights, and mount brackets.

-

before

-

-

after

Examples of Manufactured Products

Cylinder head (miniature)

2.5 mm square, 0.5 mm thick lattice structure embedded

Although strength is neglected, if specifications can be shared, it is possible to reduce the weight other than where strength is required.

Suspension arm

Lattice structure embedding of 2.5 mm square and 0.5 mm thick (image model)

-

High rigidity type

The parts that are not necessary for strength are made into a structure, so that the shape maintains strength.

-

Weight-saving type

Since this model also specializes in weight reduction, strength is ignored.

RR WING (miniature)

5.0 mm square, 0.5 mm thick lattice structure

-

Modeling as it is

-

Blade section thinning and internal lattice structuring

Because the base parts are extruded aluminum, the figures for weight reduction are low, but there is still room for weight reduction.

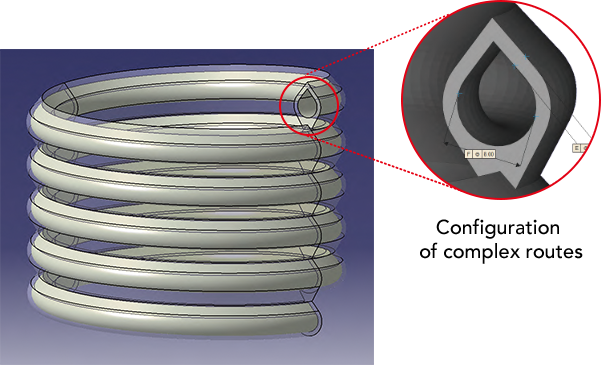

Spiral cooling shape

Wall thickness 1.5 mm inner diameter φ8 + drop shape

Enables highly efficient cooling with a thin water-cooled cooling path. Proposal of a shape that models the internal path without support material.

Free shapes that match the mating parts are also possible.

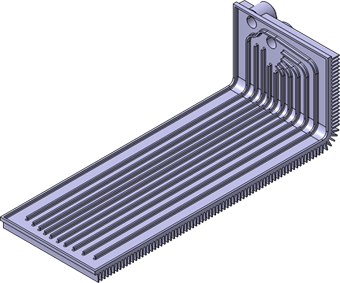

Heat exchanger model

Free designing is possible. Please consult in any form.

Polyhedral, simultaneous cooling can be realized.